Charles Sturt University EPC 2

Conservia achieved a cost savings of $26,554 which was $8,074 (or 43%) in excess of

the guaranteed cost savings set out in the Energy Performance Contracting (EPC) Stage 2.

EPC Financial

Deferred Project Cost: ~$132,860

Cost Savings: ~$18,480/yr

Simple Payback: 7.2 years

EPC Outcome

Achieved Cost Savings: ~$26,554/yr

Cost Savings: $8,074 (43%)

GHG Savings: 211 tonnes/yr

Project Summary

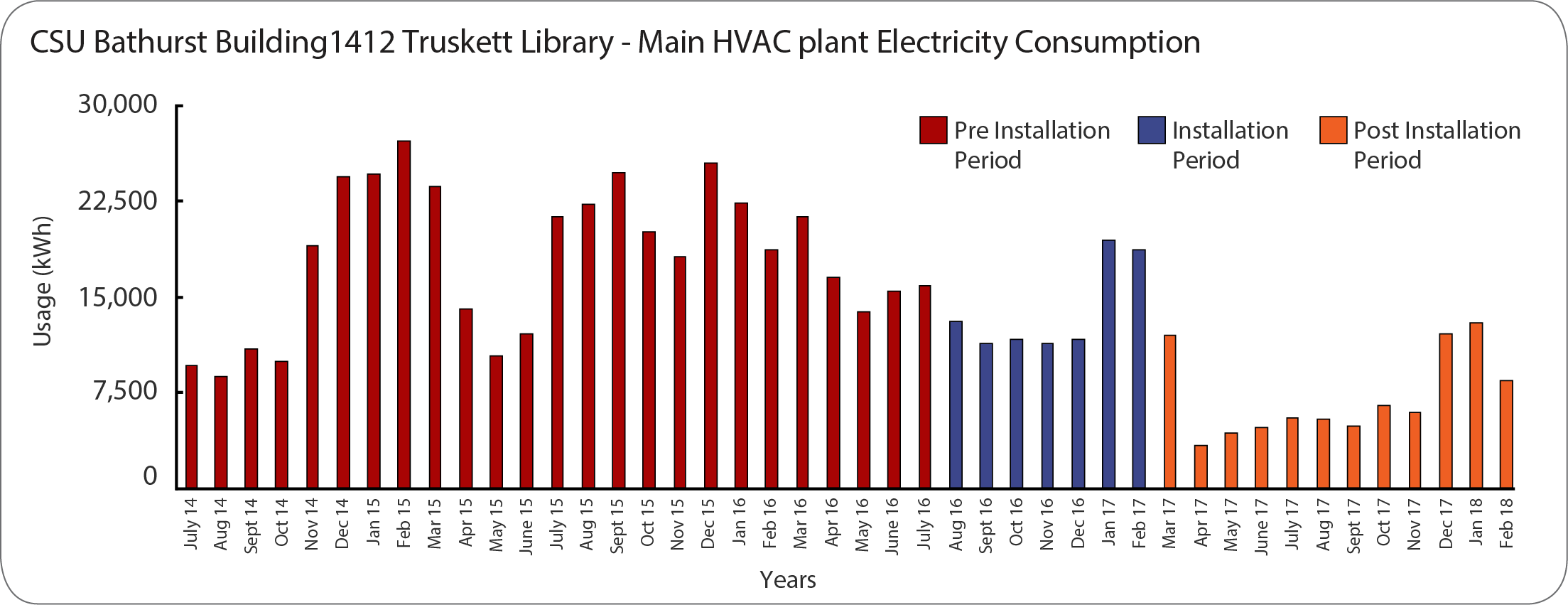

Charles Sturt University (CSU) engaged Conservia to design and implement the installation of a high efficiency centralised chilled and heating hot water system, replacing the existing inefficient centralised chilled and heating hot water system. The existing water cooled chiller with reciprocating compressors and phased out Refrigerant R22 was replaced by an efficient air cooled chiller with two semi hermetic screw compressors with Variable Speed Drives(VSD’s) and R134a. The existing end of life boiler was replaced with a new efficient boiler.

All existing Air Handling Unit (AHU) fans and new chilled water/hot water pumps were installed with VSD’s. The Building Management System (BMS) was upgraded with energy savings options such as optimum start/stop, chilled/hot water temperature resets, demand ventilation with CO2 sensors. Light Emitting Diode (LED) panel lighting was installed in the Level 3 offices and Level 5 bookshelves area, replacing T8 fluorescent with magnetic ballast troffers.

The Opportunity

CSU was certified as the first Carbon Neutral= University in Australia in July 2016 against the National Carbon Offset Standard (NCOS). CSU has earned its certified Carbon Neutral status through years of planning and investment in people, systems and infrastructure. This EPC 2 project was one of several projects to achieve it.

Key Energy & Water Conservation Measures (ECM’s & WCM’s)

• Replacement of the existing water cooled chiller with R22 and cooling tower with a new high efficiency air cooled chiller with high part load efficiency including new chilled water circulating pumps with high efficiency motors and VSD’s

• Replacement of the existing hot water heater with a new high efficiency forced draft hot water heater including new circulating pumps with high efficiency motors and VSD

• Replacement of the existing central air handling system (AHU-1) with new AHU’s (AHU 1a and 1b) with VSD’s and high efficiency motors

• Installation of high efficiency motors and VSD’s on other air handling units

• Installation of high efficiency motors and VSD’s on chilled water and hot water pumps

• The BMS system was upgraded with energy savings options such as optimum start/stop, chilled/hot water temperature resets, demand ventilation with CO2 sensors

• Installation of LED panel lighting in the Level 3 offices and Level 5 bookshelves area

Energy/GHG Savings

Electricity Savings = 183,300 kWh/yr (Proposed 111,570 kWh/yr Achieved 71,730kWh/yr excess)

Natural Gas Savings = 480 GJ/yr (Proposed 461 GJ/yr Achieved 19 GJ/yr excess)

GHG Savings = 211 tonnes/yr (Proposed 148 tonnes/yr Achieved 63 tonnes/yr excess)