Charles Sturt University EPC 1

Conservia achieved a cost savings of $176,831 which was $19,723 (or 12.6%) in excess of the guaranteed cost savings set out in the Energy Performance Contract (EPC) Stage 1 electricity, natural gas and water consumption savings.

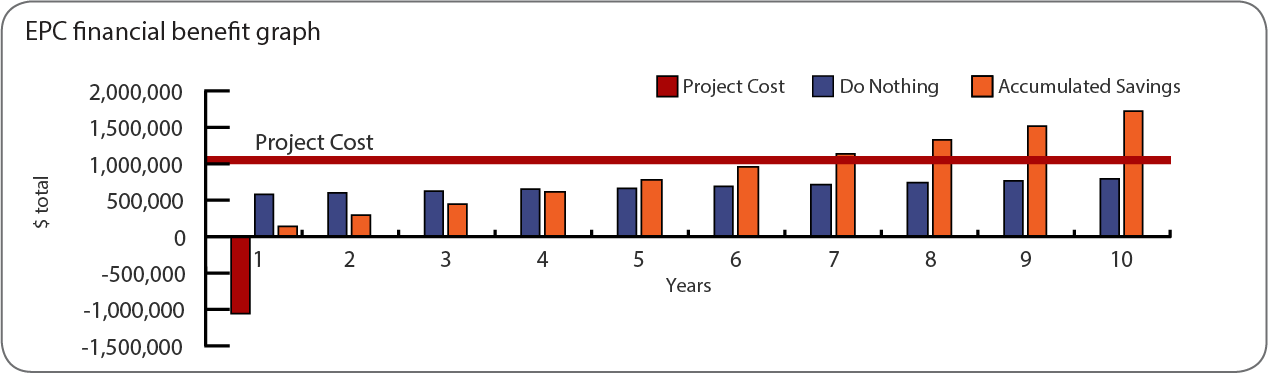

EPC Financials

Project Cost: ~$1,100,000

Cost Savings: ~$157,000

Simple Payback: 7 years

EPC Outcome

Achieved Cost Savings: ~$176,831/yr

Cost Savings: $19,723 (13%)

GHG Savings: 1,077 tonnes/yr

Project Summary

As part of their efforts to drive carbon neutrality, Charles Sturt University (CSU) engaged Conservia, selected from a panel of three Energy Services companies after a thorough selection process to deliver an EPC project. The project was implemented in late 2015 and included the installation of energy and water conservation measures in 17 buildings across CSU’s Bathurst and Wagga Wagga campuses.

A range of buildings with different operational characteristics were considered. The buildings considered were Libraries, Administration buildings, Student Centres, Laboratories and Accommodation.

The Opportunity

CSU was certified as the first Carbon Neutral University in Australia in July 2016 against the National Carbon Offset Standard (NCOS). CSU has earned certified Carbon Neutral status through years of planning and investment in people, systems and infrastructure. The EPC 1 project was one of several projects undertaken by CSU to achieve the target. The EPC identified a number of energy and water conservation measures that could be implemented to generate energy savings, through efficient energy management and operational improvements via fine-tuning.

Key Energy & Water Conservation Measures (ECM’s & WCM’s)

• New Building Management System (BMS) controls

• Modification of constant volume systems to variable volume systems thus reducing reheating

• Installation of demand ventilation (CO2 based control)

• High level interface control with the variable refrigerant volume air conditioner units

• Integrated occupancy based lighting and heating, ventilation, and air conditioning control

• Installation of variable speed drives on air handling unit fans, chilled water pumps, condenser water pumps and cooling tower fans

• BMS fine tuning with optimum start/stop and temperature resets

• Installation of efficient T5 fluorescent lighting, Light Emitting Diode (LED) down lights and LED external flood lights

• Installation of occupancy based lighting control

• Installation of solar hot water preheating

• Installation of flow restrictors on taps

Energy/Water Savings

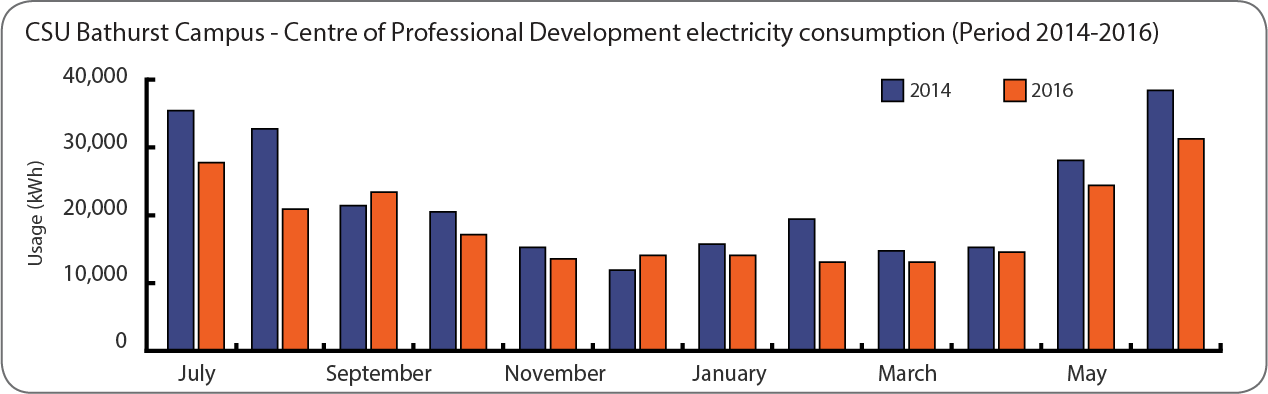

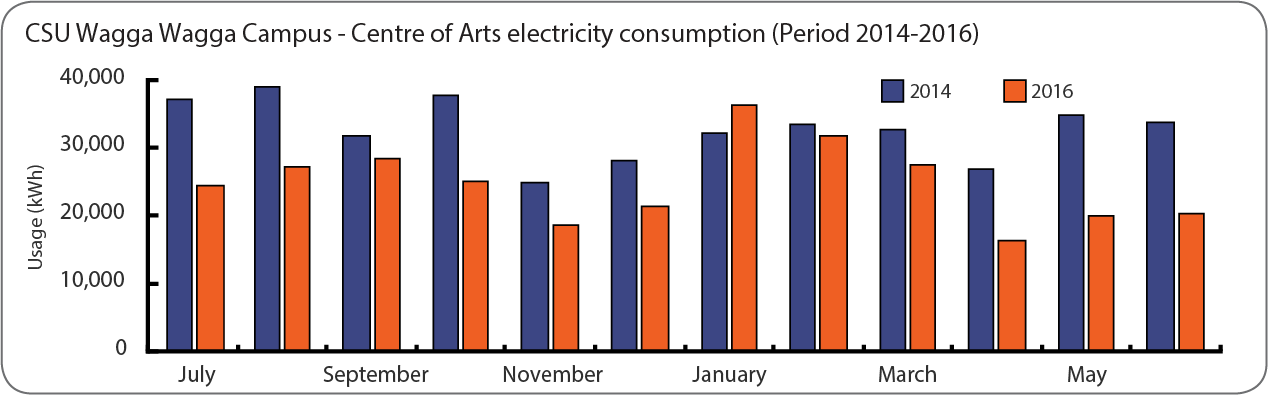

Electricity Savings = 813,548 kWh/yr (14% of total and 3.6% in excess of proposed)

Natural Gas Savings = 4,106 GJ/yr (30% of total and 93% in excess of proposed)

Water Savings = 740 kL/yr (16% of total and 3.6% in excess of proposed)